PVC wrap uses environment-friendly resins

Environmental superiority of PVC wrap among petroleum-based plastics

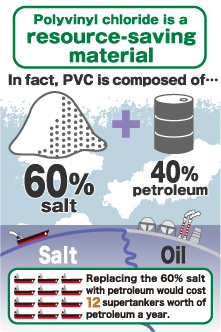

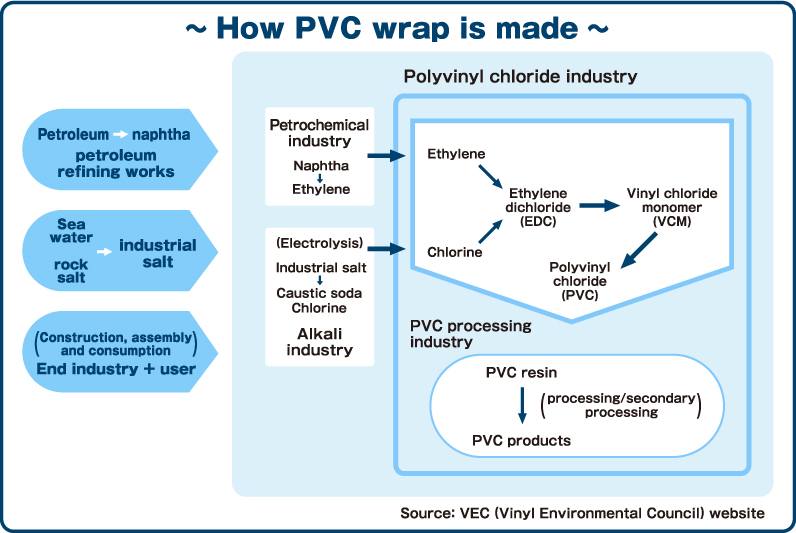

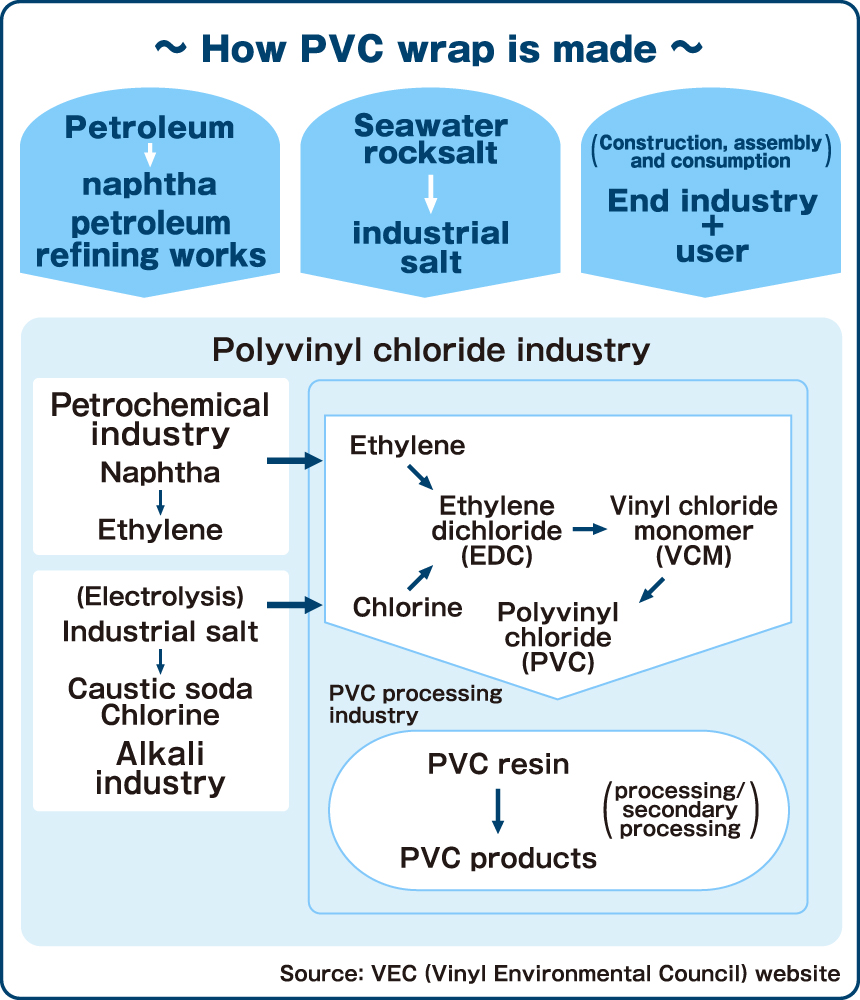

Chlorine (cℓ), derived from natural salt (Nacℓ) abundant on earth, accounts for approximately 60% of the materials that compose PVC resin.

Unlike many other plastics fully produced from petroleum, using salt which exists inexhaustibly on earth for 60% of the raw materials largely contributes to the economy of limited petroleum resources.

PVC wrap has overcome environmental problems

Dioxins

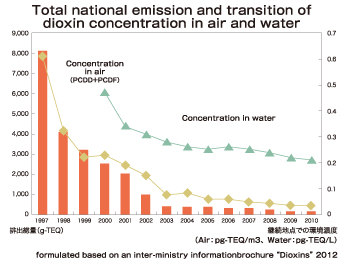

While polyvinyl chloride contained in waste had been considered to be the cause of dioxin generation as chloride contains dioxins, chloride is not just polyvinyl chloride’s specialty; it can be found in many other products such as food, seasonings, papers, clothing and so on. Therefore, improvement of incinerators was crucial in controlling dioxin production. In 1999, the government enacted the Act on Special Measures against Dioxins (Dioxin Act) and improved/developed incinerators and as a result, Japan’s dioxin emission decreased by approximately 98% in 2010 as compared to 1999.

Concerns regarding endocrine disruptors

Endocrine disruption effects of phthalate ester compounds widely used as a plasticizer and nonylphenols used as a stabilizer in PVC products have been denied by the Ministry of Environment’s research “Strategic Programs on Environmental Endocrine Disruptors ’98 (SPEED ’98) ”. Plasticizers used in PVC wrap are adipate compounds and do not include any of phthalate ester compounds or nonylphenol stabilizers.

Trend of reviewing polyvinyl chloride resins

Revision of Green Purchasing Guideline

According to the materials disclosed by the Green Purchasing Network , dioxin issue became a hot social concern at about the same time as the formulation of GPN purchasing guideline which began in 1996, and polyvinyl chloride (PVC) was presented as one of the causes of dioxin generation, creating the demand for more information. From such social backgrounds, we had laid PVC as one of the topics of which information to be provided in the GPN purchasing guideline. However, with the recent social trend and knowledge, it has been decided by the Technology Information Council through discussions that provision of information on PVC for reasons regarding dioxin generation will be discontinued and this was approved in the 94th GPN Board of Directors Meeting held in November. Each guideline was revised by the GPN.

*Click here for more information on the announcement that polyvinyl chloride (PVC) is no longer going to be the topic of which information to be provided.

http://www.gpn.jp/archives/gpnnews/archive/2013/11/000518.php

Safety of PVC wrap is assured

Safety of PVC wrap

With respect to PVC wrap, there is no denying fact that plasticizers transfer to food easily when they come in contact with oily/fatty food, as it uses plasticizers for 30% of its material to add flexibility. In response, we have established our original standard at an industrial association JHPA (Japan Hygienic PVC Association) and manufacture using only the registered additives of which safety has been secured within the restricted amount. Standard values are stipulated through material tests and dissolution tests based on a method prescribed by the Ministry of Health, Labour and Welfare Notification No. 370 . All of our PVC wraps satisfy the specifications and have acquired a certificate of verification from the JHPA.

Safety of plasticizers

The “Fact Sheet ”, or outline based on scientific knowledge regarding the safety of food drawn up by Cabinet Office food safety committee is currently publicly available. “Fact Sheet” was made based on the research results of that time and it contains information about substances which elute from plastic wraps. A quarterly journal “Food Safety ” vol. 39 touches on the safety of plasticizers that the plasticizer with the highest detection frequency and the largest amount of residual was found to be diisononyl adipate in 1999 through analysis of PVC wrap film for commercial use and for home use sold in stores which were used for wrapping perishables in domestic supermarkets, and that these plasticizers including bis(2-ethylhexyl) adipate (DINA) widely used overseas have low acute toxicity and their genotoxicity as well as carcinogenicity have not been detected.

*Click here for more information on the announcement of Fact Sheet

https://www.fsc.go.jp/sonota/factsheets/factsheets_wrapfilm_140331.pdf

*Click here for more information on the content of the quarterly journal “Food Safety”

http://www.fsc.go.jp/sonota/kikansi/39gou/39gou_2.pdf

Strengths of PVC wrap

PVC wrap is easy to use with excellent elasticity, resiliency and self-adhesiveness

| Category | PVC (For Commercial Use) | Single-layer PO | Triple-layer PO | Measurement Method | |

|---|---|---|---|---|---|

| 1 | Elasticity (ability to be stretched) | ◎ | △ | ○ | JIS.K-6732 23±2℃ |

| 2 | Strength | ◎ | △ | ○ | JIS.K-6732 23±2℃ |

| 3 | Self-adhesiveness | ◎ | ○ | ○ | Our original testing method |

| 4 | Rollability | ◎ | ○ | ○ | Evaluation by packaging machine |

| 5 | Lubricity | ◎ | ○ | △ | Evaluation by packaging machine |

| 6 | Packing machine cuttability | ◎ | ○ | ○ | Evaluation by packaging machine |

| 7 | Heat sealing property | ◎ | △ | ○ | Evaluation by packaging machine |

| Elasticity (ability to be stretched) | |

|---|---|

| PVC (For Commercial Use) | ◎ |

| Single-layer PO | △ |

| Triple-layer PO | ○ |

| Measurement Method | JIS.K-6732 23±2℃ |

| Strength | |

|---|---|

| PVC (For Commercial Use) | ◎ |

| Single-layer PO | △ |

| Triple-layer PO | ○ |

| Measurement Method | JIS.K-6732 23±2℃ |

| Self-adhesiveness | |

|---|---|

| PVC (For Commercial Use) | ◎ |

| Single-layer PO | ○ |

| Triple-layer PO | ○ |

| Measurement Method | Our original testing method |

| Self-adhesiveness | |

|---|---|

| PVC (For Commercial Use) | ◎ |

| Single-layer PO | ○ |

| Triple-layer PO | ○ |

| Measurement Method | Evaluation by packaging machine |

| Lubricity | |

|---|---|

| PVC (For Commercial Use) | ◎ |

| Single-layer PO | ○ |

| Triple-layer PO | △ |

| Measurement Method | Evaluation by packaging machine |

| Packing machine cuttability | |

|---|---|

| PVC (For Commercial Use) | ◎ |

| Single-layer PO | ○ |

| Triple-layer PO | ○ |

| Measurement Method | Evaluation by packaging machine |

| Heat sealing property | |

|---|---|

| PVC (For Commercial Use) | ◎ |

| Single-layer PO | △ |

| Triple-layer PO | ○ |

| Measurement Method | Evaluation by packaging machine |

◎Excellent ○Average △Poor